-

A futuristic bench almost unattainable for traditional techniques created for the Puerta Barqueta real estate development in Seville confirms the potential of architectural 3D printing.

-

Palimpsest, a term derived from the Greek “to engrave anew,” refers to parchment that was once used and then scraped clean to make way for new text. The concept of palimpsest also extends to an archaeological phenomenon where layers of human activity accumulate over centuries, creating a historical tapestry. Seville, a city that flourished as the largest urban center in Europe during the Middle Ages, embodies the essence of a living palimpsest. Throughout history, various civilizations, including Phoenicians, Greeks, Carthaginians, Romans, Visigoths, and Arabs, were drawn to its strategic location along the banks of the Guadalquivir River.

Today, the Barqueta Bridge, which played a prominent role in the inauguration of the Expo 92 universal exhibition, connects the technological polygon of La Cartuja with the city’s mainland. It leads to the site where the old Almenilla or Barqueta gate once stood, constructed by the Almoravids. In 1873, a residential complex was erected on its original spot, later renovated by the architect José Espiau y Muñoz in 1924.

However, ACCIONA is now on a mission to breathe new life into this historical area and propel it into the 21st century. With the ambitious Puerta Barqueta project, we have recaptured the essence of Espiau and Muñoz’s original design while integrating the latest cutting-edge technologies. The result is a groundbreaking creation: a unique piece of furniture that blurs the lines between a bench and a sculpture, taking pride of place in the block’s inner courtyard, serving as a symbolic meeting point.

The innovative furniture piece, with its elegant, sinuous forms and surprisingly lightweight, has been masterfully manufactured using the revolutionary 3D printing technique known as contour crafting. This addition becomes a new layer in Seville’s palimpsest, destined to etch its mark in the city’s history books.

-

-

The heart of Puerta Barqueta

The Puerta Barqueta project strikes a balance between preserving the charm of early twentieth-century Seville and embracing a contemporary aesthetic. The structure’s exterior showcases strips of exposed brick, reminiscent of the city’s architectural heritage, while exuding a sense of clarity and sleekness. However, it is within the interior courtyard where the true heart of the building lies.

The question that arose was how to honor this extraordinary space truly. Typically, the design of urban furniture pieces constructed with concrete involves molds and formwork, often leading to mass production. Yet, it was evident from the outset that we required a distinctive element that would encapsulate the essence of the entire project. This realization prompted us to turn to our 3D printing technology, enabling us to bring to life a bench with curved lines that would have been unattainable through traditional manufacturing methods.

-

3D printing technology enabling us to create a bench with curved lines that would have been unattainable through traditional methods.

-

-

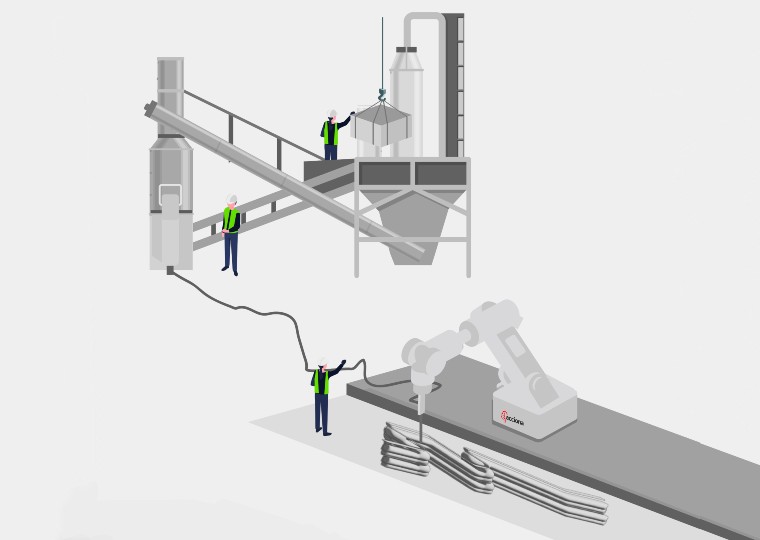

How contour crafting works

Achieving these remarkable curves demands the integration of several mechanical elements. Firstly, a material collection system introduces the dry mortar, serving as the concrete base. This dry mortar is then transferred to a gunite machine, where it is mixed with water and a retardant.

The challenge lies in striking the perfect balance: ensuring the mixture does not set too early, which could lead to clogging the 3D print head, while also preventing it from setting too late, causing the concrete to deform under the weight of subsequent material layers.

-

Once the concrete mix is prepared, it is pumped to the robot head via the gunite mixers. One mixer is mounted on a stationary bed, while the other moves along a twenty-three-foot-long track. Each mixer deposits successive layers of concrete, building up the intricate design. After twenty minutes, the part is fully formed, ready to be transported the following day.

-

3D printing: the key to sustainability

The absence of formwork and reduced concrete usage inherently fosters a more sustainable construction approach. Furthermore, on-site module manufacturing significantly reduces the carbon footprint of transportation. Additionally, the flexibility of 3D printing enables experimentation with different concrete mixes, aiming to incorporate waste and recycled materials to enhance project sustainability further.

-

-

-

Street furniture to give cities a unique personality

The 3D printing technology we use has already proven its versatility by creating canopies, urban furniture like acoustic screens, and even vertical gardens on facades to combat noise pollution. However, the potential of these 3D printers extends further. Our upcoming project involves building a demonstration home in Chile using local raw materials, with the entire robotic installation transported by ship to the construction site.

In the years to come, 3D printing will revolutionize urban landscapes, offering endless possibilities, from innovative building facades to designer street furniture. It’s time to embrace the possibilities and start dreaming in 3D.

-

-

What if the world could build itself?

At ACCIONA, we are experts in designing a better planet, and we are developing innovations to try to achieve that goal. Want to find out what they are?

-

-

-

-