-

Building infrastructure from composites or sustainable materials is one of the objectives of ACCIONA.

-

We are walking through an unending labyrinth of streets flanked by hundreds of buildings crammed around us. They are towers over 30 meters high – 10 or 11 stories – protecting us thankfully from the sun’s suffocating heat. No, we are not in the Chicago Loop, nor the Hong Kong quarter of Tsim Sha Tsui or San Francisco Financial District. We are in Manhattan, but not that Manhattan. This is Shibam in Yemen, the Manhattan of the desert, and these skyscrapers were erected 1,700 years ago.

The old walled city of Shibam, in the southern Arabian Peninsula, is the oldest model of urban planning based on vertical construction. The perspective from a bird’s eye view is spectacular: a rectangular walled enclosure bursting with a chaotic forest of giants made from mud. Outside the walls, the Ramlat al-Sabatain desert stretches for many miles in every direction, until our gaze becomes lost in the horizon.

Today, Shibam is a small Yemeni town of 7,000 inhabitants whose strange skyscrapers led Unesco to designate it as a World Heritage Site in 1982. Yet it is also a successful example of the application of composite materials, and although it is by no means the oldest documented, it is nevertheless one of the most fascinating.

The buildings of Shibam were built between the 4th and 16th Centuries AD with adobe, which is basically a mixture of clay and mud. It consists of the first composite made by man and although the research and development of composites, the typology of their components and resulting uses have evolved exponentially, the definition remains the same: composites are made from two or more elements in a way that combining them yields a new material that can be put to greater use than any of the individual components alone.

-

Composite materials

Like the Arab engineers of that time, ACCIONA understands that composites give rise to a wide range of possibilities and that the most innovative and sustainable future will go hand in hand with the future of composites. For this reason, ACCIONA is equipped with two production facilities for manufacturing composite material components and structures and they also conduct life-size trials.

The company is researching and developing to become a leader in the composite materials field. It works mainly with carbon fiber, glass fiber and polymeric materials, and, using processes such as hand lay-up, pultrusion, RTM (Resin Transfer Molding) and infusion of thick laminates, the ACCIONA Technological Innovation department has achieved great progress in several areas.

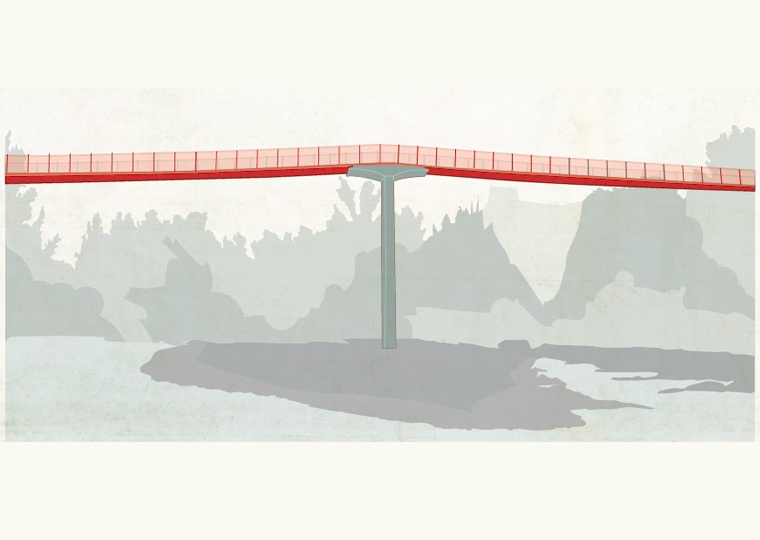

Through the use of composite materials, ACCIONA can replace traditional materials such as steel and concrete for beams, cables, bars or forged structures in its works, with composites among other materials, and this brings about substantial improvements throughout the whole constructive process. Composites are much lighter, avoid corrosion problems, offer great mechanical resistance, high versatility and electromagnetic transparency, etc. – benefits that translate into swifter and easier assembly and more sustainable construction.

Design, manufacture and installation of composites form the bridge towards the future of innovation, sustainability and great achievements. A perfect future. A composite future.

-