-

Find out why ACCIONA is a world leader in the design, assembly and use of tunneling machines, constructing a future world with greater guarantees of success.

-

In the second half of the 19th Century, a visionary named Jules Verne dreamed up marvelous machines and ingenious artifacts, and anticipated situations that wouldn’t be realized for many years if not decades later.

His most famous creations included the bathyscaphe Nautilus in Twenty Thousand Leagues Under the Sea, the helicopter Albatross from Robur the Conqueror and the space cannon in From the Earth to the Moon. All these devices later inspired engineers and inventors to create the automatic submarine, the passenger plane and spaceship.The adventures related by the French writer led their protagonists to places never imagined before, such as the bottom of the sea, outer space or Journey to the Center of the Earth. In this last extraordinary scenario, not even the great Jules Verne could devise a vehicle to transport Professor Otto Lidenbrock and his nephew Axel safely as they explored underground.

In the novel, published in 1864, the German mineralogist leads an expedition to discover fantastic worlds in the lower layers of the Earth’s crust. Although in that time there were already primitive machines able to break up rock, and innovations in excavation technology, it is certain that not even the most brilliant minds could have imagined that, just 20 years later, the submarine would be invented, or almost a century on and we would have a rocket to outer space, never mind gigantic, non-stop cylinders that could drill through the earth and take their occupants to unknown destinations, while transforming the chaotic scenario behind them into a safe passage for explorers to come.

-

Tunnel boring machines: Constructing a new world

The technological evolution of tunneling machines, which accelerated at the end of the 19th Century and finally took off in the first half of the 20th, contributed greatly to the expansion of land transport worldwide. The excavation of tunnels to break through mountain ranges or circumvent difficult passes facilitated the ferrying by rail and road of passengers and freight, with their subsequent social and economic benefits.

The construction of this new world would not have been possible without tunnel boring machines, which would be nothing more than science fiction if it were not for a handful of companies that have been designing, every day for many years now, veritable works of art in the name of engineering.

At the head of the group of dreamers of our time, you will find ACCIONA. Its leadership in the construction of roads, railway lines and suburban trains has seen the company become one of the leading experts in building every kind of tunnel.

-

-

Different types of tunnel boring machines

One of the crucial factors, when working with tunneling machines, is choosing or adapting the right machine for each lay of the land. This skill of selecting the specific equipment for each project is what makes ACCIONA a world leader in the sector. Maximiliano Arenas García, Director of Construction and Technical Director of the Business Unit Specialized in Railways and Tunnels at ACCIONA, explains that the first step is to determine what kind of earth the machine will come up against. For example, if it consists of competent rock, the main problem will be the hardness or degree of resistance of the element, whereas, in an environment where water is present, the difficulty will reside in establishing a front for the excavation. To meet all these challenges, in any location in the world, ACCIONA has different types of tunnel boring machines (TBMs): open-type Main Beams, single shield, double shield, earth pressure balance, hydro shield, and so on. And its engineers and technicians are able to adapt them to any eventuality the project presents.

-

-

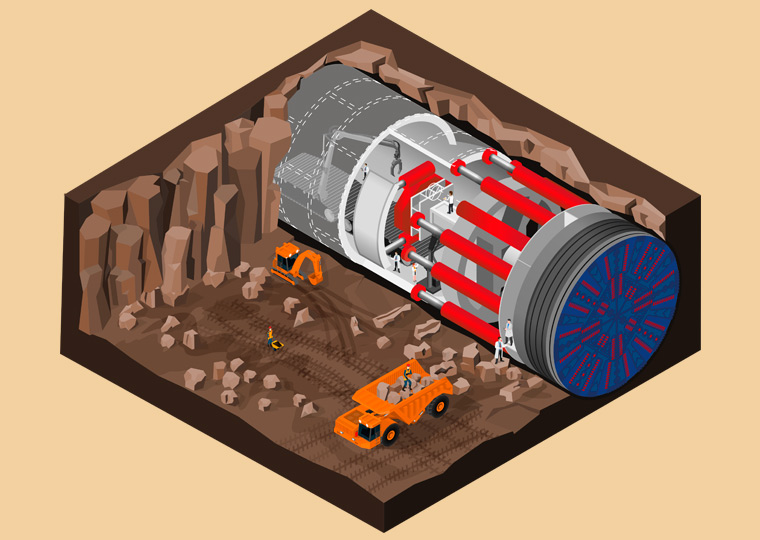

What are these tunneling machines like?

These machines have become colossal in size, worthy of admiration in themselves. They reach up to 100 meters long, typically with excavation diameters of 18 meters, and can weigh 2,800 tons. That is, they can be as long as nine buses, as high as a five-story building and heavy as 15 Boeing 747s. Some 20 people can be working inside the machine at the same time and, since they work non-stop around the clock, a total of up to 140 people can work on a tunneling machine in different shifts.

Watching these gigantic cylinders open up the Earth is a unique spectacle. No less astonishing is contemplating how they leave behind them a structure of perfectly assembled segments that hold up the tunnel safely.

And, in production terms, ACCIONA’s tunneling machines are powerful beasts, boring through over 1,000 meters of rock a month.

-

Did you know that up to 140 people work in shifts inside a tunnel boring machine?

-

-

Flagship projects with tunnel boring machines

Of the over 600 kilometers of tunnels ACCIONA has drilled in recent times, the tunneling machines have had a key role, accounting for more than a third of the total production.

These excavators have taken part in some of ACCIONA’s most emblematic projects, such as the Legacy Way highway in Australia, rail tunnels in Oslo (Norway, the Follo Line) and Bologna (Italy), and the metros of Fortaleza (Brazil) and Barcelona (Spain). They have also drilled access ramps to mines, irrigation tunnels, and water supply and collector networks.

The use of TBMs has reaped huge benefits in these and other works the company has carried out in all kinds of locations. Their use increases safety, reduces landslides and associated damage, and results in greater drilling performance. It means we can now complete a tunnel in a single stage, with a better-quality finish.

The machine that even Jules Verne was unable to imagine allows ACCIONA to construct the world of the future with greater guarantees of success.

Visit the ACCIONA website to get to know more stories like this.