-

Discover Europe’s biggest floating caisson-building dock, able to construct docks and quays of over 200 meters long within a month

-

Human history runs parallel to the development of maritime navigation. From the dawn of the first peoples born to sail – the Greeks, Phoenicians and Vikings – ancient civilizations expanded their nautical frontiers using natural refuges, like inlets, bays and large estuaries offered by rivers, to shelter from the inclement seas and oceans.

As naval exploration went on to demand havens of greater depth and size, technical innovation gradually allowed them to adapt and optimize strategic coastal enclaves more to man’s taste: Roman port technology, which included vertical, mass concrete docks, or the stone ports of Tyre and Sidon, raised in 13 B.C. using such a magnificent procedure that their main sections still exist today, are good examples.

Later, commercial routes opened, run by the different Companies of the Indies following the discovery of America, steamships were introduced and expanded rapidly to the detriment of sailing vessels, and luxury passenger lines emerged. Today navigation continues to be a key transport mode for cargo and passengers.

-

As the centuries passed, Phoenicians, Greeks, conquistadores, businessmen and travellers alike always sought to dock in a safe port after weeks of crossing the ocean; and, as maritime services continued to increase, so did the needs of the anchoring points. Possessing a big capacity port, with easy access and safe shelter, is therefore a great asset of coastal cities worldwide where naval traffic represents an important economic driver; and building one quickly with the least possible environmental impact has become de rigueur for those who have made port engineering a work of art.

-

-

Craftwork on a large scale

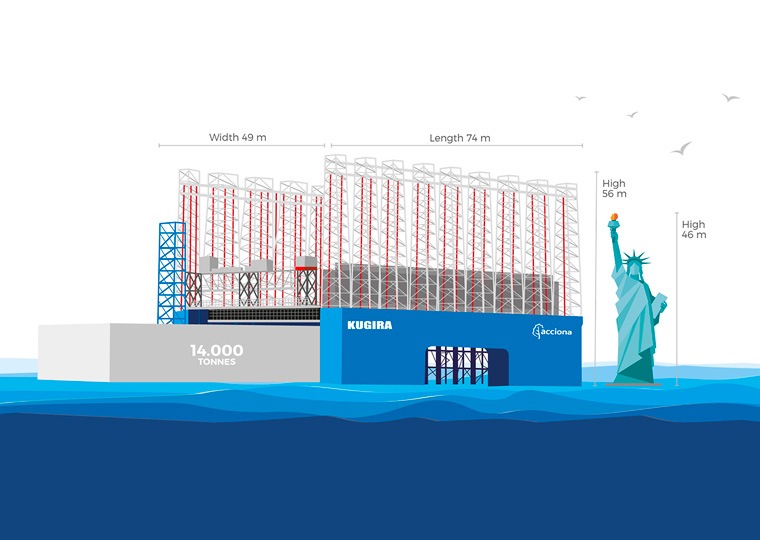

Standing almost 60 meters high, over 74m long and 49m wide, Europe’s biggest floating caisson-building vessel builds and extends ports, quays, inlets and docks the world over. This is Kugira – the name of which means whale in Japanese – ACCIONA’s giant artisan that plies the responding to the call wherever there is a need for craftwork on a large scale.

The visual spectacle of Kugira is matched only by its extraordinary productivity: 200 people working around the clock every day to build the biggest reinforced concrete caissons on the planet in just ten days week: giant blocks of 14,000 tonnes, 66.5 meters long, 30m wide and 34m high. Put another way, in just one month the Kugira can build a 200-meter seawall or jetty from nothing.

-

The Kugira builds ports with up to 50% savings in raw material resources

-

-

-

The best option whatever the job

Why is the floating caisson-building dock owned by ACCIONA the best option when building or extending a port? The statistics speaks for it. First, the Herculean structure works from the sea, hardly interfering at all with the normal port traffic and thus without prejudicing economic activity during the work.

In addition, the impact on sea life is much less with Kugira than during works carried out using conventional methods. Similarly, consumption of raw materials is less and, depending on the nature of the work, this can mean savings of 50%, with the consequent environmental as well as economic benefit.

As for the usual disturbances that arise in this type of venture, noise, pollution and the possibility of on-site accidents are considerably reduced with the Kugira, which carries out the work up to four times quicker than that done conventionally.

Through craftsmanship on a large scale, the Kugira is transforming the world’s ports into safer harbours for the navigators of our time.

Visit ACCIONA to discover more stories like this one.