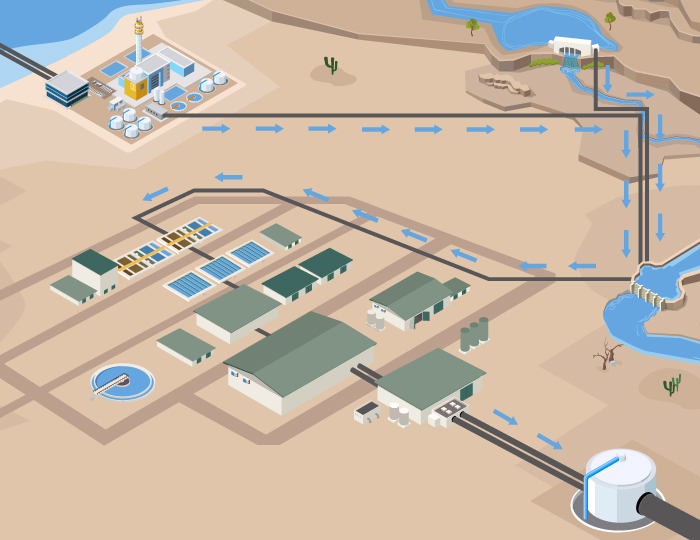

From the reservoir to the tap

Each day, the Mundaring DWTP can treat up to 165,000 m³ of water, with the potential to expand in the future to reach 240,000 m³. It exclusively supplies water to GAWS through a main pipeline 600 kilometers long and almost half a meter in diameter, branching into over 9,000 kilometers of pipes to reach all users. However, two main purification processes are applied to ensure optimal conditions for farmers, ranchers, consumers, and industries.

First, a pretreatment removes solid particles through coagulation, flotation, and filtration. The sludge from this phase is not wasted, as we’ll see later. On the other hand, once these impurities are removed, the organic content, as well as odors and tastes, are reduced thanks to the Activated Carbon BioFilters. Finally, bacteria, viruses, and microorganisms are deactivated through chlorination and other chemical treatments, which also enhance the water's taste quality. This process includes the addition of fluoride and pH correctors.

Thanks to the employed technologies, the amount of chemicals used is minimized, preventing the excessive formation of chlorine byproducts in the long distribution network. This is accomplished by reducing organic matter without the use of chemicals, unlike other conventional DWTPs.